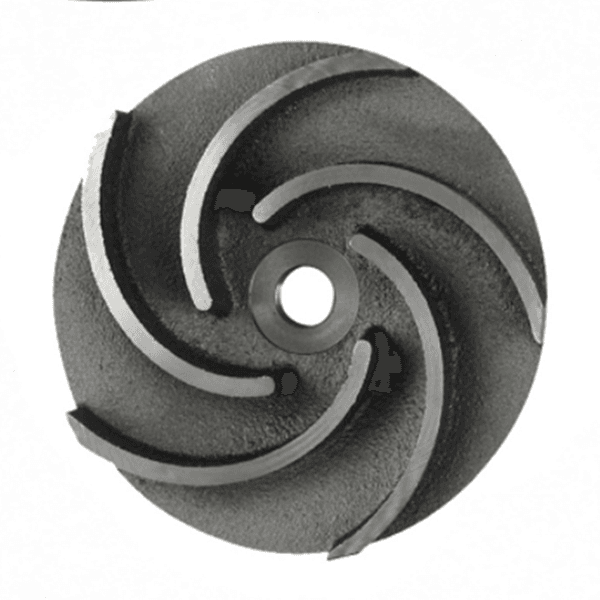

pump impeller

High-Quality Pump Castings: Custom Solutions for Industrial Applications

We also specialize in manufacturing premium pump castings and components, engineered to meet the rigorous demands of various industries. Our product range covers key parts such as pump casings, impellers, volutes, pump bodies, and mounting brackets — all precisely crafted using advanced casting technologies and high-performance materials.

Product Range Includes:

- Cast iron pump parts

- Industrial pump components

- Sand casting pump parts

- Ductile iron pump volute

- Pump impeller

Introducing the impeller

1. Cast Iron Impeller

- Material and Appearance

- Made of cast iron, it has a dark gray, rough surface typical of cast iron products. The impeller features a circular shape with several curved blades extending from the center to the edge in a spiral pattern.

- Functional Characteristics

- Fluid Movement The curved blades are designed to accelerate the fluid (such as water) as it passes through the impeller. When the impeller rotates, it creates a centrifugal force that draws in fluid from the center and pushes it outwards through the blades, increasing the fluid’s pressure and flow rate.

- Strength and Durability Cast iron provides good strength and wear resistance, making it suitable for handling relatively abrasive or high – pressure fluids in general industrial or municipal water – handling applications, like in sewage pumps or water supply pumps for lower – to – medium – pressure systems. However, it may be prone to corrosion in highly acidic or alkaline environments over time.

- Typical Applications

- Commonly used in pumps for sewage treatment plants, where it can handle fluids containing solid remnants (to a certain extent, depending on the design). Also applicable in some water circulation systems in industrial facilities where the fluid is not highly corrosive, such as in basic cooling water loops.

2. Stainless Steel Impeller

- Material and Appearance

- Constructed from stainless steel, it has a shiny, metallic silver – gray surface with a smooth finish. The design is also circular, with a more compact and streamlined structure compared to the cast iron one. The blades are integrated into the impeller body in a way that forms internal channels for fluid flow.

- Functional Characteristics

- Corrosion Resistance Stainless steel’s primary advantage is its excellent corrosion resistance. It can operate in aggressive fluid environments, including those with acidic or alkaline fluids, seawater, or fluids containing chemicals that would quickly corrode cast iron.

- Efficiency in Fluid Handling The smooth surface of stainless steel reduces fluid friction, which can improve the overall efficiency of the pump. The design of the blades and internal channels is optimized to minimize energy loss during fluid acceleration and redirection, making it suitable for applications where high efficiency and reliability in corrosive conditions are required.

- Hygienic Properties In addition to corrosion resistance, stainless steel is easy to clean and sanitize, which makes it ideal for use in pumps in the food and beverage industry, pharmaceutical industry, or any application where the fluid must meet high – purity standards.

- Typical Applications

- Frequently used in pumps for the food processing industry, such as in milk or juice processing lines, where the fluid must not be contaminated by the impeller material. Also used in marine applications (for handling seawater), chemical processing plants (for pumping corrosive chemicals), and in pharmaceutical manufacturing for transferring high – purity fluids.

Whether you need cast iron pump casings for water transportation, stainless steel impellers for corrosive media handling, or ductile iron volutes for high-pressure systems, we can provide custom solutions. Each component undergoes strict quality control: spectrometers ensure precise alloy composition, and tempering heat treatment enhances hardness, wear resistance, and strength.

Our pump castings are applied in key fields such as oil and gas extraction, petrochemical processing, water treatment, waste disposal, and concrete construction. We deliver solutions that combine durability, reliability, and excellent performance for both standard and custom requirements.

Contact us today to obtain OEM pump casting solutions — from sample development to mass production, we guarantee on-time delivery and consistent quality.

Related Products

Related products

Why Choose Us

With over 30 years of expertise in casting production, we combine rich experience with strict quality control to ensure every product meets the highest standards. Our commitment to green production drives us to adopt environmentally friendly processes and technologies. Additionally, we offer flexible customization capabilities to deliver solutions tailored to your specific needs.